Linkedin

Linkedin

Facebook

Facebook

Twitter

Twitter Together making the world greener

02 June 2025

The Environmental Campaigner Laura Young, Circualr Economy Minister Mary Creagh and Graeme Milne CEO of Ecogenesys joined SWEEEP Kuusakoski to cover the launch of 1 June 2025 disposable vape ban.

Laura Young video of the film came out great and well worth a watch:

https://www.linkedin.com/posts/laurabethyoung_bandisposablevapes-singleusevapes-activity-7334902459238158336-AWcx?utm_source=share&utm_medium=member_desktop&rcm=ACoAABA86GMBzPU5snBEuB7Dw1-nKWbOHhWF71g

© 2025

02 April 2024

Household hoards of unused electricals and broken tech are growing, a recycling campaign group warns.

Material Focus estimates we've gone from stockpiling an average of 20 items to 30 within four years.

Its findings come from market research. The top ten products include remote controls, mobile phones and hairdryers.

With the UN reporting that electronic waste is rising five times faster than documented recycling, we're being urged to clean out our "drawers of doom".

Paul Bowtell says he keeps finding unused electricals in his house "I think back in the day my dad would have had a shed full of jars of screws, and the modern dad has a drawer full of 15 old mobiles," says Paul Bowtell, a self-proclaimed hoarder of electricals.

He counted more than 40 electrical items in just a couple of his storage boxes.

But there's more, he admits, in the attic, drawers, a footstool and other boxes.

The Bristol dad says there are things he's looking after for his grown-up sons, and items which were once expensive and now hold no value, so it's hard to say goodbye.

Scott Butler, executive director of Material Focus, says we've probably all got a "drawer of doom", which has "got cables in there that we don't know what they're for: it's got a DVD remote for a DVD player that we lost a long, long time ago".

The group - which runs an electricals recycling campaign and postcode search for householders to find drop off points - estimates over 880 million unused items are being held in UK homes. It warns trashed electronics should never go in the general waste.

"If you look at the electricals that we're throwing away and that we're holding onto [in the UK], we think over a £1bn billion in value of 'treasure', is sitting there untapped," says Scott Butler. "That material is also quite crucial for the green technology future that we're aiming for."

Inside old laptops, electric toothbrushes and shavers is a trove including steel, aluminium, copper, lithium batteries and even gold.

Justin Greenaway, commercial manager of SWEEEP, a specialist household electrical recycling centre, says that whenever there's anything complicated going on inside a computer, with lots of data moving around, all the connections need to be finished with gold to stop the data becoming corrupted.

"Our process allows us to recover that gold and get it back into use again. Obviously if we don't capture it and it goes into landfill or incineration that gold is lost."

Mining such precious materials in the first place leads to pollution, harms wildlife and contributes to climate change, as extracting raw materials, followed by manufacturing them into products is very carbon intensive.

"It's not just about recycling electricals... It's about getting the value out of them," Sarah Burns, the sustainability and engagement manager from Bristol Waste says. "The first thing we would look to do is to reduce the electrical items in the first place."

One way of keeping unused electrical items in circulation to extend that value, is to share them. For example, at Share Bristol - A Library of Things, instead of borrowing books you can borrow sanders, hedge trimmers and popcorn makers amongst other items you're unlikely to use every day.

Anna Perry says every household has a collection of unused and broken electricals

Anna Perry, one of the trustees, donated her jet washer to the scheme.

"I knew that a jet washer would be well used and really popular, but I didn't think my jet washer would be used for 19 different projects by 19 different people," she explains.

Even redundant laptops can find new homes, once they've been wiped of data.

"If you're lucky enough to have a spare laptop or smart device, search "recycle your electricals" and you'll see reuse and drop off points where people can donate to those in need," adds Scott Butler from Material Focus.

Data from Material Focus suggests households are throwing away 103,000 tonnes of electricals, rather than recycling them.

The organisation also estimates that 343,000 tonnes of electrical waste is being stolen from within the waste system or illegally exported.

To calculate the estimates on what we're holding onto, Material Focus used data from recent market research where 2,000 adults were polled across the UK by companies that are members of the British Polling Council.

Video from BBC Breakfast can be viewed here:https://www.linkedin.com/posts/justin-greenaway-6ab29a77_great-work-again-from-the-team-at-material-activity-7179046441078640642-56Va?utm_source=share&utm_medium=member_desktop

© 2024

11 March 2024

Recycling minister opens ring crusher at SWEEEP Kuusakoski site

The Defra minister with responsibility for recycling, Robbie Moore, officially opened SWEEEP Kuusakoski’s £3 million ring crusher last week (7 March) at its Sittingbourne recycling facility.

The ring crusher pulverises motors/transformers from waste electronics to separate copper, plastic, ferrous and aluminium.

Transformers are often incorporated into electronic devices to step up or down the voltage for the device’s operation, while motors can be found in devices like vacuum cleaners, lawnmowers, cameras, printers, and computer peripherals.

Small mixed WEEE is a POPs waste so any output containing plastic, cable or circuit board is also a POPs waste. Motors/transformers all have a small plastic content and the ring crusher is capable of separating that plastic into the copper smelter concentrate for POPs compliant destruction.

It is estimated that all the UK small mixed WEEE contains approx. 10,000 tonnes of motors/transformers per year. The SWEEEP Kuusakoski ring crusher has a 50,000 tonnes annual capacity and thus offers plenty of capacity to also recycle other WEEE components like LDA motors when the BASEL changes restrict exports.

Crusher

The ring crusher originated from its parent company Kuusakoski’s Philadelphia site in the USA. It was transported in 10 shipping containers, totalling a weight of 120 tonnes. Upon arrival, SWEEEP Kuusakoski’s engineering team rebuilt and refurbished the ring crusher within a span of 4 months.

After opening the facility, the recycling minister Robbie Moore said: “It’s essential that we improve our use of resources – ensuring that more valuable materials are reused and recycled in the UK.

“We’re taking action on this, and recently introduced new proposals to make it easier for the public to recycle old household electrical goods. But it’s crucial that we work closely with industry to make our recycling goals a reality, which is why it’s so encouraging to see this new facility open today. Copper is a vital resource and SWEEEP’s work will ensure that more of it stays in the UK to be reused, rather than sent abroad.”

Regulations

SWEEEP Kuusakoski’s highlighted that technology like its ring crusher is important in light of upcoming changes to the BASEL regulations on 1 January 2025 as the separation of copper from WEEE components could serve as a valuable domestic resource for the UK.

The change to the regulations will mean all shipments of WEEE components, hazardous or not, will require prior informed consent when the regulations come in.

‘Recycled’

Justin Greenaway, commercial manager at SWEEEP Kuusakoski, added: “The SWEEEP Kuusakoski Ring Crusher is a strategically important infrastructure installation. It will liberate low carbon and resource efficient copper from a complicated POPs impacted waste.

“Copper is one of the most critical basic metals required for the electrification of the world. Demand for copper is estimated to rise by up to 50% between now and 2040. Producing copper from ore causes 10 times more carbon emissions compared to using recycled materials.”

Treatment

At the event on Thursday there was also a string of leading industry figures.

This included Martyn Parfitt, operations manager at Electrolink Recycling, who noted: “It is great to see this level of investment in a different process for treating and processing WEEE within the UK. This initiative will prevent the need for export of valuable critical materials and ensure the necessary high levels of treatment standards.”

Infrastructure

Meanwhile Nigel Harvey, chief executive at the compliance scheme Recolight, said: “It is great to see SWEEEP making such an important and strategic investment into copper recovery. The availability of copper will become increasingly vital as the UK decarbonises energy supply systems and increases electricity distribution infrastructure.”

‘Delighted’

Graeme Milne, director at Repic concluded: “I’m delighted to work with Justin and the team at SWEEEP. They continue to invest in class leading recycling infrastructure which serves Repic and our members well.”

Original lets recycle article here: https://www.letsrecycle.com/news/recycling-minister-opens-ring-crusher-at-sweeep-site/

© 2024

24 January 2024

SWEEEP Kuusakoski and Recycleye announced the first successful commercial application of AI computer vision in the detection and sorting of WEEE (Waste Electrical and Electronic Equipment) in the UK. This announcement brings the use of artificial intelligence for automated sorting to WEEE and metals, which although is increasingly being used to sort household waste, has not yet been widely applied to WEEE or metals.

SWEEEP Kuusakoski, based in Sittingbourne, Kent, specialises in the recycling of waste electrical and electronic equipment. Recycleye is a ground-breaking technology company bringing AI-powered automated sorting to waste and materials management. Together, the companies deployed an optical sorter that uses AI and machine learning to innovatively sort e-waste for recycling.

Whilst existing optical sorters in waste facilities already use pneumatic ejection, the integration of the technology with AI rather than NIR is novel to this application. Using AI to detect objects means they are identified by a range of visual features, just like a human eye, rather than by purely colour and light-based sensors.

In WEEE, this means that the new technology can detect PCBs compared to other pieces of metal and plastic, so precious metal content can be extracted for recovery. Historically, existing optical sorters have struggled to identify PCBs accurately when broken into small fractions, and so AI-powered ejection is now equipping metal recyclers like SWEEEP with new capabilities.

Similarly, the multi-material nature of batteries makes them difficult to detect with NIR, and often a manual task. Yet AI has the potential to detect and eject batteries based on visual features, reducing the risk of ignition during the recycling process.

At SWEEEP’s site in Sittingbourne, Recycleye’s AI-powered optical sorter is installed at the back-end of the plant, sorting between higher value items with precious metal content, namely copper, PCBs, cables and brass, and lower value materials, such as aluminium, plastics, steel, ferrous metals and batteries. By ejecting the lower value materials through AI-powered detection, the system is cleaning up SWEEEP’s valuables line to support purer waste streams.

This installation to sort SWEEEP’s shredded e-waste is the first time that Recycleye has combined its AI with an air jet system, and marks the first step that the innovative companies are taking together in evaluating the impact of AI on WEEE sorting.

Speaking about the innovation, Barry Walker, Chief Executive Officer of SWEEEP Kuusakoski said “This innovation will not only increase the value of our material output, but also safeguard our staff and facilities as the AI vision operates 24/7 to detect batteries. As one of the UK’s leading electrical equipment collection and recycling specialists, we are confident that the additional purity this investment achieves will enable us to supply even greater volumes of low carbon and resource efficient raw materials back into the circular economy.”

Commenting on the new partnership, Zoe Cook, Technical Sales Manager (UK) at Recycleye, said “This is an important milestone for the use of our AI and sorting technology. This successful application in the sorting of WEEE demonstrates that AI-powered sorting automation can be utilised to tackle even more waste categories, due to the flexibility to adapt machine learning models to different streams”.

Nice news coverage here: https://www.letsrecycle.com/news/recycleye-and-sweeep-use-ai-for-waste-electrical-sorting/

© 2024

08 December 2023

In Nov 2023 we did some filming at SWEEEP Kuusakoski with The Independent and North London Waste Authority. Our industry knows all the data of course but great to have a wider audience thanks to The Independent TV.

Vapes were originally touted as a cheaper and safer alternative to tobacco, and while they still serve this purpose, they’ve become a defining image of throwaway culture.

Around five million single-use vapes are thrown away every week in the UK - a fourfold increase on 2022. This amounts to eight vapes being discarded every second, according to research by Material Focus

Disposable vapes are difficult and expensive to recycle, spelling disaster for the environment and local councils, who are struggling to cope with the amount being thrown away every day.

Watch the video here: https://www.independent.co.uk/tv/news/vapes-disposable-recycling-environment-b2459632.html

© 2023

23 June 2023

After a 15- day journey starting in Alness in the Scottish Highlands, the cyclists of Repic’s WEEE Cycle Network event reach the finish line in Sittingbourne, Kent on Friday, 16 June.

The final leg of the event was from Bexleyheath to the finish line at SWEEEP Kuusakoski’s Gas Road treatment facility, where Louise Grantham, chief executive of REPIC, led the riders across. A special applause went to Andy Kellar, Repic’s contract services manager, who was the sole pedal bike rider to complete the entire 15-day, 850-mile journey.

Louise Grantham, chief executive of REPIC, commented: “The unwavering commitment and enthusiasm of the Repic team and all our guest riders to complete this 15-day journey have truly made this an experience to remember. I hope the experience, friendships and camaraderie built over these 15 days will continue to inspire and further support the sector’s advancements in developing a more circular economy for electricals.”

Landscape

Repic launched the event to reflect on the changing landscape of the country since the release of the first WEEE regulations in 2007. Through the event it aimed to show the significance of responsible electrical waste management and driving the sector towards a circular economy.

Moreover, the event served as a platform for contemplating the future of electrical reuse and recycling in the UK. Participants had the opportunity to exchange ideas and contribute to the forthcoming WEEE consultation, facilitating informed decision-making and strategic sector planning by bringing together industry experts and policy makers.

Justin Greenaway, commercial manager at SWEEEP Kuusakoski, the final event host and one of the ten cyclists on stage, commented: “We are honoured to have been asked to host this milestone stage and have been fully supportive of all the positive stories that have been told about the sector over the past 15 days. It’s important to take time out to reflect just how far the sector has travelled and developed, and what we’ve learned, and I’m grateful to have enjoyed and participated in this experience with REPIC.”

Repic and its sponsors pledged to donate a total of £15,000 to various local good causes along the 15-day Repic WEEE Cycle Network event route, to contribute to the betterment of communities and reinforcing the positive impact of responsible electrical waste management.

More pictures and full article here: https://www.letsrecycle.com/news/repic-weee-cycle-network-finishes/

© 2023

23 March 2023

A nationwide TV advertising campaign aiming to tackle e-waste began yesterday (22 March 2023) when a Recycle Your Electricals advert was aired on ITV and Sky.

The advert, which can be seen: http://youtu.be/PXZ1w35aF-I, forms part of Recycling Your Electricals’s behaviour change campaign, which aims to reduce the 155,000 tonnes of small electricals discarded every year.

Campaign

Recycle Your Electricals is a UK-wide campaign “motivating and making it easier for everyone to reuse and recycle unwanted electricals”.

The campaign is led by Material Focus, an independent not-for-profit organisation funded by the WEEE compliance fee. The compliance fee is paid by obligated producers if they are short of having enough evidence to hit targets.

Scott Butler, executive director at Material Focus, leading the Recycle Your Electricals campaign, said: “We are throwing away some of the most precious materials on the planet when unwanted electricals get binned. And this has to stop, now.

“We want everyone to know that they should never bin and should always recycle their electricals. Love or loathe him, HypnoCat is broadcasting on UK radio and TV screens with a mission to stop people in their tracks and to compel them to start recycling. He is bright pink, proud, loud and mesmerising. My kids and even Wally the dog have already been seduced by HypnoCat. For me he is the purrfect ambassador for our campaign. I challenge you to watch him and not end up reciting the whole thing for days after.”

Advert

The new advert debuted yesterday across the ITV family and multiple Sky channels, supported by radio (Absolute & Heart), and social media.

For the advert to work Material Focus says it needs to “not only tell people to stop binning and start recycling their electricals, but highlight the key electricals people don’t even think of as electricals, like toothbrushes and toys”.

The advert also needs to motivate people and give them a reason for doing it, the group added, by showcasing what they can be recycled into.

David Gamble, Truant London co-founder, helped create the advert and said: “HypnoCat was born to solve a tricky behavioural problem. His sole purpose is to stop people from binning their electricals and start recycling them.

“He allows us to say very functional and direct messages in a fun and engaging way. His catchy trance track and mind-bending visuals are hard to ignore, while his repetitive lyrics are even harder to forget. Just ask my kids. They’ve been singing it for weeks. Apologies in advance, parents. But if everyone starts to recycle their unwanted electricals, we promise to make him stop.”

Campaigns

Formerly known as the WEEE Fund, Material Focus is a not-for-profit organisation.

It was created in January 2020 and launched the public-facing Recycle Your Electricals campaign in May 2020

From article:

https://www.letsrecycle.com/news/nationwide-tv-campaign-launches-to-tackle-weee/

© 2023

15 November 2022

Over 1.3 million disposable vapes a week are ending up in landfill or incineration. SWEEEP help raise the profile of this problem by hosting ITV and https://www.materialfocus.org.uk

Watch the video here:

https://www.itv.com/news/2022-11-14/where-do-disposable-vapes-end-up-when-theyre-thrown-away

© 2022

26 May 2022

July 2022 SWEEEP Kuusakoski will be 15 years old!

As a celebration of this milestone and to thank everyone who has contributed to the success of this company, dinner is on us.

26th July 11 am - 8.30pm you will be able to enjoy a choice of meal plus drink from our visiting mobile catering van.

There will be a fresh serving per shift.

Vouchers will be available from your shift manager on the day or via Weighbridge for drivers

© 2022

06 April 2022

Many thanks to all the drivers who have been patiently waiting for us to finish our new weighbridge office – the disruption is now over!

It has taken just under 5 months from knock down to rebuild. Top service from Chris Browne builders providing quality workmanship as always. Also a big thanks to Countrstyle Recycling for managing the waste from the project and helping us achieving best environmental outcome

© 2022

01 October 2021

Watch the video here: https://youtu.be/QmJi-KMA48s

Brexit combined with the impact of COVID has given SWEEEP Kuusakoski a challenge to achieve full staffing numbers. We wanted to show the variety job roles and career progression opportunities available at SWEEEP Kuusakoski and what better way than getting this first-hand direct from our own team members.

Directing, Filming, voice over and editing by our very own talented staff - Adrian Baluse and Dzintars Granapskis. Jess Nakielska and Fraser Daniels turned into presenters for the day by being filmed giving a guided tour and outline of their own career progressions.

Adrian “I loved every second of it and I would like to thank everyone involved for their dedication and hard work”.

Dzintars “It was an unforgettable experience and absolute pleasure to see some really impressive talents develop”.

The video will be used by our staff sourcing agencies as an introduction to our company with a hope that the enthusiasm captured on film will translate to new starters at SWEEEP Kuusakoski.

© 2021

08 September 2021

Calling all EV driving visitors to SWEEEP Kuusakoski – you can now plug in and charge while taking a tour and drinking coffee with us!

We have 4 charging points at 22kw with type 2 connectors. Our roof mounted array of solar panels feed into our electric combined with renewable energy via: https://lnkd.in/dGX9G8yt

Our car chargers can be reserved for you prior to a visit – just mention when confirming dates with your main point of contact at SWEEEP Kuusakoski

© 2021

30 July 2021

Smoke alarms in Small Mixed WEEE.

The Environment Agency Small Mixed WEEE Storage and Treatment Guide 413_14 (March 2014) was written to help EA Officers with BATRRT compliance at sites which handle small mixed WEEE. The document covers the main storage and treatment requirements for small mixed WEEE using Best Available Treatment Recovery and Recycling Techniques (BATRRT).

Even though published in 2014 the guide was a good starting point for compliance monitoring and highlighted “Radioactive substances must be removed prior to treatment. The main source in SMW is likely to be from ionization smoke detectors”.

SWEEEP Kuusakoski are finding approx. 1 smoke alarm in every 5 tonnes of small WEEE.

Some of those smoke alarms are radioactive waste containing americium-241 which emit Alpha particles. Alpha particles are sub‑atomic particles. The range of alpha particles in the air is up to 1 inch, and they can even be blocked by a piece of paper.

A domestic smoke alarm tucked inside a rollonoff with 5 tonnes of small mixed WEEE is very unlikely to set off a weighbridge radioactive sensor.

SWEEEP Kuusakoski find smoke alarms only by a manual rigorous pre-sorting of the small mixed WEEE. This is labour intensive and thus expensive.

SWEEEP Kuusakoski use https://www.acb.co.uk to recycle our smoke alarms and incur a per unit charge.

Justin Greenaway, Commercial Manager SWEEEP Kuusaksoki "It is a major financial saving if a small mixed WEEE Recycler simply ‘never finds any smoke alarms’. There are some excellent AATF's doing what we do and finding the smoke alarms but equally I have concerns some small WEEE recyclers are simply not checking.I would encourage both EA and WEEE PCS to use smoke alarm segregation as a KPI for proper treatment of small Mixed WEEE.

© 2021

12 April 2021

Fresh article published on Lets Recycle from SWEEEP:

https://www.letsrecycle.com/news/latest-news/opinion-where-are-the-missing-batteries/

Where are the missing batteries?

The obviously wrong lead acid battery protocol is undermining the collection of truly portable batteries. This in turn undermines treatment quality at WEEE AATFs and increases fire risks in outputs from recyclers where batteries remain a contamination.

The implausibly high collection rate of portable lead batteries (1,367T put on market but 11,470T recycled in 2020!) is well known to the industry and the regulators https://www.letsrecycle.com/news/latest-news/battery-collection-target-for-2020-within-reach/ but the wrong protocol continues to be used because collection targets can be achieved on the cheap.

Producer responsibility legislation is complicated to get correct, and I sympathise with the logic that why would a producer take more responsibility than legally required by collecting batteries in excess of targets? This then loops back to lead acid battery protocol needing fixing to make sure all stake holders are motivated to collect.

True portable batteries are available to collect but approx. 3661 tonnes of batteries are hiding in our electronic gadgets (Small Mixed EEE).

If the Small Mixed WEEE gets incinerated, then batteries don’t get recycled

If the Small Mixed WEEE goes to landfill, then batteries don’t get recycled

If the Small Mixed WEEE gets exported, then batteries also get exported

If the Small Mixed WEEE gets recycled to a poor-quality standard, then batteries are lost into other outputs

Looking at the numbers:

There is 0.68% battery content in typical Small Mixed WEEE. The official figure of 0.68% comes from hand sorting trials sourced from a wide geographic area in order to obtain representative samples. For the past 2 years SWEEEP Kuusakoski have had our battery capture rate independently verified – 80,000T of a sample size achieved 0.73% battery capture rate. The national protocol of 0.68% battery content is therefore both accurate and achievable but you need to have a lot of staff sorting to find all the batteries.

Small Mixed EEE (Put on Market) 2020 = 538,477T x 0.68% = 3,661.64T of batteries held inside our gadgets. If more Small Mixed WEEE was recycled then more batteries could be recycled: https://www.letsrecycle.com/news/latest-news/where-missing-weee/

3,661.64T is a significant weight of batteries held inside Small Mixed EEE which turns into Small Mixed WEEE if like for like old for new. The National Packaging Waste Data base confirms that in 2020 Battery Compliance Schemes collected 17,728T of batteries but true portable batteries (Ni-Cd + Others) not skewed by lead acid protocol was 534.681T + 5722.906T = 6257.587T

Recycling more Small Mixed WEEE correctly via AATF infrastructure is critical to being able to reach battery targets once lead acid protocol fixed.

Crucially the quality of recycling at AATFs must also be measured to ensure 0.68% is being achieved. This has never previously been audited by the EA in any meaningful way but 0.68% as a KPI is planned as part of BATRRT refresh.

WEEE Producer Compliance Schemes also have a role to play in checking that a robust battery capture system is in place at all AATFs. Where a WEEE PCS is also a Battery PCS you would expect a shared interest in checking battery capture rates are being achieved – that is joined up producer responsibility in action.

SWEEEP Kuusakoski’s independently audited battery capture rate % report (0.73% across 80,000T of Small Mixed WEEE) has been shared with all our key customers. You do however need to apply a lot of labour to capture all the batteries and it is significantly cheaper not to capture all the batteries when recycling Small Mixed WEEE.

Small Mixed WEEE 2019 recycled via AATFs = 137,022T x 0.68% battery content = 931T of battery potential.

Small Mixed WEEE 2020 recycled via AATFs = 108,933T x 0.68% battery content = 740T of battery potential.

Battery Compliance schemes will know how much battery tonnage has come from AATF during the last 2 years and it should have been around 931T+740T = 1671T

SWEEEP Kuusakoski has captured 574T of batteries out of small mixed WEEE during the last 2 years. All recycled via battery schemes and contributing to battery capture rate data.

Batteries are small incendiary devices and there are almost weekly reports of fires in commercial transfer stations, scrap yards, household waste sites and waste collection vehicles. All stake holders are impacted by fire caused by batteries and we all have a role to play but step one must be to stop using the obviously wrong lead acid battery protocol.

© 2021

17 February 2021

After 7 years of hard work hand collecting broken TV screens from household waste sites our collection vehicle gets a refresh.

We have continued with the theme of helping to communicate the importance of recycling waste electronics. Amazingly the latest survey from Material Focus confirms 48% of the UK public don’t know that you can even recycle electronic waste.

Anyone seeing the simple message on the curtains should understand the call of Don’t bin it, Recycle it!

© 2021

09 December 2020

The small WEEE consumer awareness HypnoCat video is now finished. We are super pleased with the result and I am sure more small WEEE will get recycled as a consequence. Thanks to all our SWEEEP staff for making the video possible:

© 2020

21 October 2020

Good fun yesterday hosting the HYPNOCAT film crew. It was a long day for all of us but hopefully the results will be well worth it.

Thanks go out to our staff Jeremy Collins, Jess Nakielska and Dan Smith. Fingers crossed you all make the final cut and feature in the campaign:

https://www.recycleyourelectricals.org.uk

The aim being to encourage and support more people to reuse and recycle their old electricals.

Photos from the day here: https://www.linkedin.com/posts/justin-greenaway-6ab29a77_good-fun-yesterday-hosting-the-hypnocat-film-activity-6724627798381600768-WYqY

© 2020

09 October 2020

Justin Greenaway, Commercial Manager SWEEEP Kuusakoski: "It was a pleasure to support the campaign. We ended up with some great images to hopefully inspire people to recycle correctly"

Scott Butler, Executive Director, Material Focus: "SWEEEP Kuusakoski is one of the leading recyclers of electricals in the UK. As electricals are one of the fastest growing waste streams in the UK and globally, SWEEEP Kuusakoski have a vital role to play in ensuring that we don’t lose the valuable materials contained in our electricals forever. We are seeing more and more support for the Recycle Your Electricals campaign, and SWEEEP and other UK recyclers have got behind the campaign and remain key to our success in the future.”

© 2020

12 June 2020

“HypnoCat” will be issuing a series of rallying calls to local people including: ‘Humans of England. You will not bin your electricals’. He will also play on his cat’s superior powers over humans ‘Speaking of bags, go buy me a big bag of catnip’ in between the repeated mantra of Recycle Your Electricals. The fun character has been designed to build on a growing trend and love for bizarre hypnocats. HynoCat will also be launching in the following 4 other areas across the UK: Bristol, Bath, and North Somerset; Tyneside and Newcastle; Edinburgh and Falkirk; and Norwich in Norfolk.

Scott Butler, Material Focus, Executive Director, said: “Small old electricals are one of the fastest growing waste streams, and we are throwing away valuable materials that are lost forever. In reality, these small old, unwanted electricals contain 75% of materials that can be recycled or reused such as precious materials like gold, aluminium and steel. Through HypnoCat and our campaign we will be providing step-by-step information on how to reuse and recycle old electricals. We want everyone to know that all old electricals – that’s everything with a plug, battery or cable – can be recycled. We are calling on the nation to stop throwing away their old electricals, and instead put them in a bag ready to be recycled when your nearest recycling centre reopens.”

The Recycle Your Electricals ‘Little Spring Clean’ comes as lockdown measures have given people the opportunity to reassess their attitudes towards clearing out. Although we have become a nation of declutterers during lockdown only 20% are decluttering their old unused electricals during this time. Instead householders are focussed on sorting out clothing (65%), books and magazines (47%) and home accessories (34%). And why? We’re a sentimental, practical bunch; over a quarter listed sentimental value or nostalgia whilst almost a third keep them in case they want to use them again.

Other domestic hoarding habits revealed that:

Over a half of a million households have got 5-10 games consoles in their homes against a UK average of less than one per home

Despite many charging cables becoming obsolete over time, 1.1million of us have been hoarding them for over ten years before getting rid of them, creating a tangled mountain of 5.58 million decades old cables

Ever sat on the remote control? You’re not the only one; over 3 million homes are sitting on 5-15 of them, compared to a UK average of two per house

One of the items we are holding onto longest are old unused speakers, with almost 2 million households keeping them for over a decade

5.8 million households (21%) are holding onto VHS players

Similarly, cassette players are still being held on to in 4.7 million (17%) of homes

The Recycle Your Electricals Campaign is making recycling small old electricals easier than ever before by launching an information hub for the UK. A new postcode finder has launched on www.recycleyourelectricals.org.uk with details of over 2,000 recycling, repair and reuse points across the UK with new collection and drop-off points will be added to the site on an ongoing basis.

Share pictures, videos and stories of the electricals that you’ve collected in a bag prior to placing them at the kerbside #RecycleYourElectricals #RethinkWhatsPossible #AskHypnocat or tag us on Facebook @RecycleYourElectricals Twitter @RecycleElectric & Instagram @RecycleYourElectricals_

© 2020

15 May 2020

It was a pleasure talking with Stefanie Roßel about challenges of recycling e-cigarettes. Thanks also to RS RECYCLING LIMITED for expert knowledge and contribution. Original article here with more photos.

Recycling e-cigarettes remains a challenge

By Stefanie Rossel

While vapor products are considered to be less hazardous to users’ health than combustible cigarettes, the impact of their waste products on the environment may become just as harmful. Currently, cigarette butts are the most littered items in the world. Since the 1980s, they have consistently made up 30 percent to 40 percent of all items collected in annual international coastal and urban cleanups, amounting to an estimated 4.5 trillion cigarettes annually being discarded worldwide, according to the Truth Initiative, a U.S. not-for-profit tobacco control organization. Thrown into the environment, they leach nicotine and heavy metals while their cellulose acetate filters take up to 10 years to degrade (also see “Minimizing impact,” Tobacco Reporter, April 2019).

Due to their complex construction, e-cigarettes entail additional perils for the environment. When littered, broken vape products can ooze dangerous metals and battery electrolytes, not to mention nicotine liquid, which is toxic. The remaining plastic parts of the device take an estimated 450 years to decompose—If they disintegrate at all. Studies have shown that they break into micro particles by atmospheric conditions over time. The individual components of e-cigarettes belong in different waste categories, which can make proper disposal challenging.

In the U.S., the world’s largest vape market with a value of $6.4 billion in 2019, according to Statista, the legal situation for the appropriate disposal of vaping devices is complex and inconsistent. Most devices sold don’t include instructions on how to dispose of them correctly.

Heterogeneous rules

In the wake of vaping’s growing popularity among teenagers, littering of used e-cigarettes has become a serious problem for U.S. high schools. As students are prohibited from smoking or vaping on school grounds, they tend to do so in surrounding areas, often throwing away their discarded vape pens and cartridges as carelessly as they would cigarette butts. Schools collect the used items, which makes them “generators” of waste under the U.S. Resource Conservation and Recovery Act (RCRA).

To aid the schools in their thankless new responsibility, the Public Health Law Center (PHLC), a tobacco-control organization, in December 2019 published a guideline on how to properly dispose of e-cigarette waste. As generators, the RCRA requires schools and other institutions such as airports and courts to comply with special handling requirements, which, among other things, include that they notify their hazardous waste regulatory entity and fill out a special form to obtain a U.S. Environmental Protection Agency (EPA) identification number.

They are also required to inspect the hazardous waste on a weekly basis to make sure that there is no leakage. Nicotine, be it in the shape of a liquid or salt, is a listed hazardous waste under the RCRA. The law requires generators to ship the waste storage containers, which are not permitted to remain on site for more than 90 days, to a properly permitted hazardous waste treatment, storage or disposal facility. “While recycling the e-cigarettes would make them no longer subject to RCRA hazardous waste requirements, the problem is that, to date, no network of legitimate recycling facilities that recycle nicotine for later reuse appear to exist,” the PHLC states in its publication. “The additional burden on public institutions can be overwhelming.”

By collecting e-cigarette waste, institutions also become generators of lithium-ion batteries as they are found in rechargeable e-cigarettes. Despite their risk of fire or explosions, the batteries are not required to be stored and disposed of in the same strict manner as nicotine waste. The RCRA treats them as “universal waste,” but at the state level, hazardous waste regulatory agencies have developed different standards on how to treat them.

If used or disposed of outside one’s residence and/or accumulated by a public entity such as a school or a business, federal law uniformly treats vapor products as hazardous waste. Should students dispose of their used items at home, however, the situation is different: Under federal law, vapor devices are consumer products designed for use at a consumer’s residence in their residence and can therefore be discarded by them as nonhazardous waste. Instead, they qualify as “hazardous household waste,” which again is subject to state regulation.

To facilitate matters for their customers, several U.S. vapor companies have introduced voluntary take back programs, although some later discontinued these initiatives. Juul, which leads the U.S. vapor market with a share of around 75 percent and, according to the U.S. Centers for Disease Control (CDC), sold 16.2 million devices in 2017 alone, currently has no such program. “We are committed to developing effective, innovative and sustainable solutions,” the company told Tobacco Reporter. “We look forward to launching further takeback and recycling pilot programs in the future. In the meantime, we suggest consumers recycle their Juul devices with other electronic waste which contain lithium-ion polymer rechargeable batteries. Juul pods are not intended to be refilled and we ask consumers to not litter.”

Minimizing landfill

Regulation is clearer in the world’s second-largest vape market, the United Kingdom, where e-cigarette sales accounted for $3.2 billion in 2019, according to Statista. Despite the country’s departure from the European Union (EU) in January, it remains for the time being subject to EU laws, such as the Waste Electrical and Electronic Equipment (WEEE) regulations, which entered into force in 2014. The law aims to reduce the amount of electrical and electronic equipment ending up in landfills as hazardous materials can contaminate water and pollute soil, and the amount of landfill space in Europe is limited.

The WEEE directive sets recycling and recovery targets and requires manufacturers and retailers to assist in the collection of WEEE for recovery and recycling. Manufacturers pay an annual fee for the safe collection and recycling of electrical waste products. End-users are obliged to dispose of such products not as part of regular household waste, but by dropping them at a dedicated e-waste reception location. This can also be a retailer of electrical or electronic products as long as their shop has a certain size, or the manufacturer. To indicate that a product is required to be discarded under WEEE rules, it is marked with the image of a crossed-out wheelie bin. In 2019, a German court prohibited Juul from selling in Germany because its products lacked this symbol.

Every year, U.K. households and businesses discard an estimated 2 million tons of WEEE items ranging from washing machines to automatic money dispensers, according to the U.K. Health and Safety Executive. At present, vapor products account for only a small share of one of WEEE’s 10 broad subcategories. Listed among small household appliances, they are not even separately mentioned.

Up in smoke

Despite differing regulations, vapor product waste is submitted to similar treatments in the U.S. and the EU. “Most vape product waste, inclusive of the batteries, goes through high-temperature incineration (HTI), which means it is incinerated at 1,000+ degrees Celsius,” explains Rob Smith, owner and operator of RS Recycling Ltd, a U.K.-based company that offers destruction and brand protection services for the secure disposal of commercially sensitive, difficult, dangerous or classified waste streams. “The heat will destroy the item completely and largely reduce waste volume. There is very little residue—typically 10 [percent] to 20 percent of the inbound waste volume is outbound as an inert ash.”

In 2017, Smith was engaged by Valpak, a leading U.K. environmental compliance scheme that manages the recycling obligations of more than 5,000 U.K. businesses, to research ways of recycling vapor products. The results were sobering, Smith explains. “Recycling an e-cigarette is possible, but it’s very, very expensive. It’s a very small and tricky waste stream. If restricted to a single country, there’s a disproportionate relation of cost and R&D efforts to recycle these products.”

One reason for this is the vast variety of vapor products. In 2017, the CDC counted 565 different types of e-cigarette devices in the U.S. market, 184 of which were disposable or single-use products. While the trend has since shifted toward reusable systems, market research companies nevertheless expect disposable products to remain on the market. It was these “cigalikes” that Smith studied. “The batteries are incredibly difficult to remove from the device, and they are all made differently,” he says.

“The way they are manufactured is that the battery is tightly packed in the stem, which requires a lot of force to remove. The majority of devices are manufactured in China using lithium-ion polymer batteries, which are soft and easily damaged—around 1 [percent] to 1.3 percent of the batteries failed during removal with the possibility of catching fire if not properly dealt with by the recycler. The majority of fires in WEEE treatment facilities are thought to be caused by batteries being crushed, split or otherwise broken, or by arching and igniting surrounding combustible WEEE material,” says Smith.

Battery recycling is all about recovering the rare and valuable metals used for their production, most notably lithium and cobalt. The batteries used in vaping devices, however, are only about one-sixth the size of batteries installed in smart phones, so the commercial viability of recycling them needs to be considered.

Sweeep Kuusakoski is working on a large-scale recycling process for nicotine pods.

A costly process

Recycling a single-use e-cigarette, Smith points out, is about 20 times more expensive than burning it. “The question is whether manufacturers are willing to bear the cost,” says Smith. “There are no mechanical means currently available to take the battery out of the stem; hence a lot of costly manual labor is involved. The disposal of the nicotine liquid is also relatively expensive. Besides, there are toxic issues around that. Typically, WEEE treatment facilities are not used to dealing with hazardous toxic liquid—they have expertise in treating refrigerating gases or mercury dusts and residues, but the toxic liquids in e-cigarette cartridges present a different type of hazard and risk. Even touching the liquid with exposed skin is quite harmful.”

Reusable closed and open systems are much easier to recycle, Smith says, because they have replaceable battery packs. “Batteries tend to be stacked or are built-in in large blocks in these devices. The devices will be broken up by the conventional WEEE process, where a chain mill is used. The machine can smash the vape product so that the battery comes out and the tank can be detached from it, which makes recycling easier.” He adds that the volume of vapor products that need to be recycled is still relatively small, which hampers development of respective recovery processes. “When there are large volumes of a certain waste, it’s more likely that recycling processes are designed for them.”

Sweeep Kuusakoski, a leading WEEE processing facility in the south of England, is currently working on a large-scale recycling process for nicotine pods. The firm is a forerunner in this field, according to the company’s commercial manager, Justin Greenaway. “Working with e-cigarette responsibilities, we understand that the marketplace needs a recycling solution,” he explains. “We have already perfected the removal of batteries, using chain mills and a manual process for the disassembly of devices. Now we design a process for the cartridges to remove nicotine residue, wash out the remainders and recycle the pods.”

The retrieved nicotine fluid will be incinerated. The company had previously developed a similar system for toner cartridges, according to Greenaway. “Nevertheless, it’s a challenging task for us,” he says. “We are still experimenting, but we plan to have the process ready in three months’ time.”

Stefanie Rossel is Tobacco Reporter’s editorial contributor. An experienced trade journalist, she combines sharp reporting skills with in-depth knowledge of the tobacco and vapor industries. Prior to joining Tobacco Reporter, Stefanie was editor-in-chief at Tobacco Journal International, where she worked for a decade. Fluent in English, German and French, Stefanie covers tobacco news around the world. She is based in Germany.

© 2020, Tobacco Reporter. All rights reserved

© 2020

12 February 2020

Imagine spending years saving up enough cash to purchase a surprise present for your loved one only to accidentally recycle the electronic heater used as the safe storage place for that cash!

This is what happened to Mr Aziz Moulai who went on holiday and while on holiday the cash containing heater was recycled by his wife! A panicked call was made to Greenwich Reuse and Recycling Centre, Nathan Way London SE28 0AF. The quick actions from Veolia’s supervisor allowed the lorry load of waste electronics to be tracked and quarantined by SWEEEP Kuusakoski.

SWEEEP Kuusakoski are a large-scale waste electronics recycler in Kent processing about 150 tonnes a day of broken electronic gadgets. The cash containing delivery from Greenwich had around 3,600 items of electronic waste and finding the one item was a classic needle in haystack situation. SWEEEP’s diligent staff started sorting through the electronics late in the afternoon and then had to finish next morning when daylight returned.

The significant and life changing sum of money was found distributed through the load, but all was collected together and handed back to Aziz today (12th Feb 2020) who said “Really, I can’t find words to thank you guys…thank you so very very much”

© 2020

19 December 2019

SWEEEP Kuusakoski 2019 pool competition is completed again for another year!

More entries than ever before with just under 40 players. To add spice to proceedings any player on the winner’s trophy wall gave away 3 shots to someone not on the wall. This helps make things interesting and sees new first-time winners for 2019.

Congratulations go to:

• 1st Place: Dumitru Radu and Robert Knowski

• 2nd Place: Peter Newing and Robert Watts

• 3rd Place: Charlotte Adams and Justin Greenaway

See you all on the baize again next year.

Merry Christmas

SWEEEP Kuusakoski

© 2019

12 December 2019

Very pleased to have had Herfordshire council at SWEEEP Kuusakoski for some filming recently..... With Christmas just around the corner, now is the ideal time to remember that you can recycle old and broken electrical items such as Christmas lights, shavers, hair dryers and straighteners, just by taking them to your local Household Waste Recycling Centre. In fact, we’ll accept any household item with a plug or a battery!

Watch our short video to find out how these items are recycled:

© 2019

03 December 2019

The WEEE Christmas Treee

Margate based Zo Defferary created the WEEE Christmas Tree for Future Foundry’s Waste Free event at Turner Contemporary to highlight that over 250K (61%) tonnes of small electronic waste per year in the UK is potentially not being recycled correctly. Small electricals like phones, toys, kettles, lights, tools, HiFi and DVD players - never get into the correct recycling systems but are instead mainly lost to landfill or incineration.

As we all get excited for all our shiny new Christmas gadgets, the scary thing to ask is where does this waste go - and it’s not a good answer.

The magpie attracting WEEE waste has been loaned to the project by Sittingbourne based recycling company SWEEEP Kuusakoski, one of the UK’s leading waste electrical and electronic equipment (WEEE) collection and recycling specialist who recycle 25% of the UK’s electronics waste.

SWEEEP are desperate to encourage more of us to recycle our electronics, to salvage the precious resources, that are running out - and much easier to get from recycling than mining. It is a simple message of ‘put waste in the right place’ but that simple action allows rare earth metals and over 30 commodities to go back round again to be made into new products. We are only recycling 39% of what we could and 61% is not being recycled…….it is down to resident of planet earth to do better!

Zo Defferary creates art from waste. Inspired by calligraphy and a love for glyphic forms and markings, she draws with inanimate objects and materials referencing patterns, symbols and ornamental decorative imagery. Zo has her own ongoing salvage practice which has contributed to the tree.

Dover based https://futurefoundry.org.uk work with artists, designers and makers to enable them to use waste and salvage as a base material for their creative work. The company supply training programmes, studio facilities and their own creative salvage programme which collects waste materials and equipment for re-distribution.

© 2019

18 November 2019

Kuusakoski proudly exhibited at the inaugural E-Waste World Conference & Expo – Nov 2019. Kuusakoski has a global recycling solution and staff from Sweden, Finland, Russia, UK and USA were all on hand to answer questions from guests attending the conference.

E-Waste World Conference & Expo was a two-day international conference and exhibition dedicated to discussing the latest recycling technology, materials recovery solutions, green electronics, sustainable materials, non-toxic substitutes, and end-of-life strategies, as well as regulatory and business models to help reduce the environmental impact of all forms of consumer and industrial E-Waste.

The event brought together globally renowned experts from consumer and industrial electronics manufacturers and suppliers, E-Waste recyclers and waste management companies, recycling technology manufacturers, materials recovery experts, sustainable material and chemical suppliers, science and academia, policy-makers, NGOs, research institutions and consultants.

© 2019

21 August 2019

We are pleased to announce a further 8 staff have completed 10 years’ service with the Company and have been presented with a certificate to mark their length of service.

Since the 10 year service awards were introduced in 2017, 21 staff have been rewarded.

Staff receive a payment from the Company, a certificate and a breakfast with Barry Walker – CEO, Michael Freeman – Operations Manager and Anita Grist – HR Manager.

Left to right in main photo is:

Vanessa Hewitt

Janina Batog

Kamila Walzcak

Michael Freeman – Operations Manager

Urszula Wisniewska

Blazej Kuchnik

Daniel Korzen

Robert Knowski

Remigijus Maciulis

Barry Walker – CEO

More photos via facebook:

https://www.facebook.com/sweeepkuusakoski

© 2019

18 July 2019

We are gaining a better understanding of the hazardous in waste all the time. Gov.UK sum things up well with regards to POPs: Persistent organic pollutants (POPs) are poisonous chemical substances that break down slowly and get into food chains as a result. In the past POPs were used in various products including pesticides and industrial chemicals, and released during chemical and agricultural processes. The manufacture, sale and use of products containing POPs is now banned. The concept of Producer Responsibility is often criticised but without producers funding the environmentally sound recycling of e-waste then the cost would land with local authorities. This would ultimately then be funded by tax payers. Much better for Producers to be funding which in turn is then passed on to consumers of new goods as commercials re-balance. MRW have covered some of the challenges around the impact of POPs in this article: https://www.mrw.co.uk/latest/huge-cost-increases-in-weee-recycling-due-to-regs-shake-up/10043616.article

© 2019

30 May 2019

SWEEEP Charity Dragon Boat Saturday 7th September 2019 - staff apply now to be a SWEEEP Paddle Power Team Member.

Great fun last year and very excited to be back in the boat again with an aim for SWEEEP to raise £2000 for Charity.

© 2019

14 May 2019

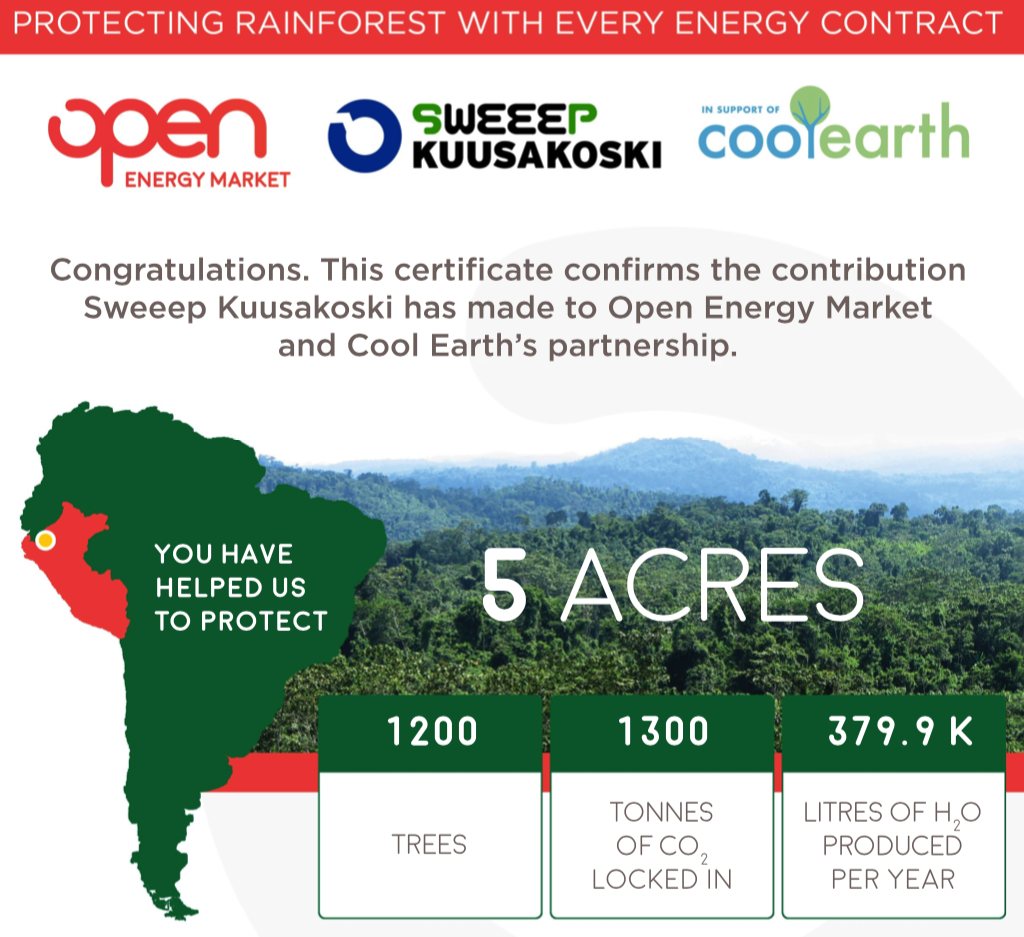

SWEEEP Kuusakoski have always powered our recycling facility using renewable energy. This year however we have taken another step with the help of https://info.openener.gy/cool-earth Our purchase of renewable energy has helped to safe guard 5 acres of endangered rainforest. 5 acres is about 1200 tress capable of locking in 1300 tonnes of CO2.

Open Energy Market is working with Cool Earth to protect endangered rainforest in Northern Peru. Every square foot of operational space at SWEEEP Kuusakoski (5 Acres) is mirrored by an equivalent area of protected rainforest

The main driver of deforestation is not global demand for palm oil, soy and timber, it’s poverty. Which is why Cool Earth focuses on addressing the drivers of degradation at the community level. By improving livelihood development, education and healthcare, Cool Earth has now placed more rainforest under the 24/7 protection of indigenous groups than any other NGO or government.

Cool Earth's 118 village partners are in control of over 900,000 acres of forest that would otherwise have been cleared. Millions of acres of further forest are now inaccessible to loggers. Add to this the 170 million tonnes of CO2 emissions prevented, the protection of 80 endangered species, and with recently winning the Charity of the Year award, I think we can safely say that Cool Earth has become a success story.

Every acre of rainforest locks in 260 tonnes of CO2

Rainforests generate a fifth of the world’s fresh water and oxygen

Half of all plant and animal species on Earth live in the rainforest

36 new species have been discovered in and around our protected areas

One in ten people on Earth depend on the rainforest for their livelihood

“The idea behind Cool Earth is that if we can help pay to conserve an acre then we can make a real difference. Perhaps the biggest difference we will make in our whole lives.” Sir David Attenborough”

© 2019

30 November 2018

After 11 ½ years of good service our old main granulator is being retired to light duties.

Today we took delivery of our new Andrirtz MeWa UG1600H https://www.andritz.com/products-en/recycling/recycling/granulator-ug

which is being installed over the next week. The granulator is virtually the last step in our plant once the Small WEEE de-pollution has happened via labour intensive hand sorting and MeWa QZ disassembly process.

Keeping any recycling facility operating reliably demands continuous investment in both quality plant and top engineering staff to maintain smooth running. This in turn allows us to give a reliable and cost-effective recycling service with best environmental outcome for our customers.

Thanks to everyone for a busy 2018.

© 2018

24 August 2018

Our 3rd TOMRA arrived today!

Continued technology advances in the gadgets we love means smaller and smarter devices become common place in our busy lives. Smaller and smarter means more complicated recycling. The good news is that TOMRA’s latest sorting equipment technology has also got smarter and embraces these new challenges.

Today SWEEEP Kuusakoski have taken delivery of our 3rd TOMRA sorter which will work in tandem with our existing metal finder at a combined sorting rate of 6 tonnes per hour. TOMRA’s intelligent object recognition controls 960 air jets all primed to sort circuit board away from plastic. End result being an exceptional level of sorting resolution, making it possible to identify even the finest particles with great precision.

You can see the technology here: https://www.tomra.com/en/sorting/recycling/products/finder

Our investment is only justifiable because of the continued support and commitment from our customers.

This is never taken for granted and always greatly appreciated.

© 2018

25 June 2018

To all SWEEEP Staff:

Charity Dragon Boat Festival 8th Sept 2018, SWEEEP Paddle Power team members apply now!

The 8th September 2018 will see the 21st annual Charity Dragon Boat Festival at Bewl Water and this is your chance to be part of our dragon boat team.

Crews of 16 paddlers (plus a drummer) race in Chinese-style Dragon Boats over a 250-metre course. Crews do not need to be super fit or skilled to be successful - all that's required is teamwork and a good sense of fun!

Your invitation will be with your next wage slip or print off from: https://www.facebook.com/sweeepkuusakoski/

See you on the water!

© 2018

12 April 2018

AATF Forum Press release – 09 March 2018

The AATF Forum represents the interests of the WEEE AATF sector and currently has 18 members representing over 80% of WEEE treatment. It’s membership is open to any AATF operator with meetings held every two months that have been recently attended by the environmental agencies, Defra, the WEEE Scheme Forum and BMRA.

The aims of the Forum are to create a sustainable WEEE processing industry by better understanding the impact of UK WEEE on the global environment and ensuring its members always follow best practice and circular economy ethos in the recycling and the reuse of WEEE.

It has been working on a number of issues that affect the effective working of the WEEE regulations and the ability for the UK to meet future targets for treatment and recycling and has formulated a response to Defra’s proposed 2018 collection targets.

In summary, the Forum believes that by simply tracking the previous year’s collection performance, Defra is failing to meet both the spirit and the environmental requirements of the WEEE Directive, namely ‘The purpose of this Directive is to contribute to sustainable production and consumption… by the re-use, recycling and other forms of recovery of such wastes so as to reduce the disposal of waste and to contribute to the efficient use of resources and the retrieval of valuable secondary raw materials.’ The proposed targets lack ambition and make assumptions that the WEEE is simply not available. The Forum asserts that there is significant leakage in the system and the lack of incentive to collect WEEE provided by the Compliance Fee has led to potentially obligated WEEE being processed through informal – and often environmentally damaging – disposal routes such as illegal exports and non-accredited ATFs. Without a robust system of WEEE management, the UK’s treatment infrastructure is at risk of lacking the investment needed for sustainable growth to ensure that high environmental standards are properly applied and maintained.

The Forum further believes that the reliance on ‘substantiated estimates’ by Defra undermines the UK’s aspiration to be an environmental leader as it effectively supports a substandard treatment regime.

The Forum has put forward proposals to Defra to add ambition back into the targets to maintain achievable growth. It recognises the challenges caused by reduced new product sales, but there is still a huge gap of 772,000 tonnes between WEEE and EEE placed onto the market that is not explained.

The Forum is also urging Defra to maximise the use of the Compliance Fee revenue raised from the 99,000 tonne shortfall on the 2017 targets to focus on identifying why so much WEEE is not being captured and to educate both householders and businesses on the need for correct WEEE disposal through a properly funded media campaign.

https://www.letsrecycle.com/news/latest-news/weee-aatf-critical-defra-targets/

Current AATF Forum Members

AO, Balcan Engineering, Eco Technology, Electrical Waste, EMR, Environcom, GAP Waste, Light Brothers, London Mining, Mercury Recycling, Recycling Lives, S Norton, Sims, SWEEEP, Veolia, Viridor, Wastecare and Wiser.

© 2018

30 January 2018

© 2018

27 December 2017

© 2017

11 July 2017

With 10 years now under their recycling belt, time has ‘swept’ by for Sittingbourne based waste electronics recycler, SWEEEP Kuusakoski. A celebration of this milestone took place on Tuesday 11th July, with Sittingbourne and Sheppey Conservative MP Gordon Henderson joining them exactly 10 years after his first visit in 2007.

Gordon said “I am delighted to join with the management and staff of SWEEEP Kuusakoski in celebrating the 10th anniversary of the recycling plant’s opening. It seems like only yesterday that I was privileged to be able to witness the new machinery that had been installed. SWEEEP is one of Sittingbourne’s employment success stories and I am proud to have been able to give the company my support during my time as Member of Parliament.”

Pam and Patrick Watts initial investment of £5M created one of the most sophisticated and environmentally robust recycling facilities in Europe. Starting with just 40 staff in July 2007 SWEEEP Kuusakoski now employ 170 full-time. This direct reflection of the huge increase of electronics now being recycled under the EU WEEE Directive, has seen the company grow from recycling the same volume now per month, as they did in their entire first year. Overall this equates to a hair raising 340 million hair dryers!

Cllr Colin Prescott, Mayor of the Borough of Swale presented long service awards to Fraser Daniels, Justin Greenaway, Diane Judd and Paul Strickland who have given 10 year’s service to the organisation saying “It is a pleasure to be here and help celebrate the 10th anniversary of this excellent company. This is just the sort of business that swale needs; innovative, environmentally aware for the 21st century and forward looking with excellent management”

Patrick Watts founder of the company, said “It's 10 years since the introduction of the WEEE directive in the UK and 10 years of Sweeep leading the way on best available treatment, compliance and efficiency. Our dedicated team has grown, as have our skills, to recycle this ever growing hazardous waste stream that returns so much back into new products.

Well done to Sweeep!

© 2017

02 September 2016

SWEEEP Kuusakoski FC win the SHIELD CUP at the 2016 WASTE WORLD CUP

24 mixed gender teams went head-to-head to win the sectors fourteenth ‘Waste World Cup’ football championship at Northampton University on Friday 2nd September.

SWEEEP Kuusakoski FC entered whole heartedly into the spirit of the event and despite some very stiff competition did not come home empty handed, yielding a very respectable Shield Trophy with a 2-0 victory in their category.

David Sidders SWEEEP Kuusakoski FC Captain said ’It was a privilege to be captain of a team with such a good bunch of people’

SWEEEP Kuusakoski FC team members on the day were: David Sidders, Alex Noble, Micky Growns, Nathan Wells, Leroy Thomas, Tony Sidders, Jack Nowiki, Radaslaw Andzejewski, Illona Rojek and Kamila Walczac

Other winners of the tournament included Wybone, who won the Plate Tournament 1-0 against SWR Waste Management, Veolia with a 3-1 win against Mick George in the Bowl Tournament, and of course B&M who won the overall Waste World cup with an impressive 4-0 against last year’s champions Valpak.

© 2016

09 August 2016

© 2016

22 April 2016

© 2016

24 June 2015

With recent changes in the WEEE directive increasing recycling targets to 45% from 2016, Valpak, Kent County Council and SWEEEP Kuusakoski stirred up a plan to take action and raise awareness of WEEE recycling in Kent. With over 7000 Sci-Fi gadget fans to press the point to, the annual Sci-Fi Festival held at Herne Bay on Sunday 21st June seemed like an ideal location to iron out any misconceptions about the types of WEEE that can be recycled. It is a simple message that anything powered by a battery or plug can be recycled for free at the comprehensive network of Kent’s household waste sites. Staff from SWEEEP Kuusakoski took the kettle by the handle and spent the day giving out leaflets promoting WEEE recycling. Lord Vader assured them he has now embraced modern recycling practises, refuting his ancient ways, and some storm troopers welcomed the WEEE directive with next stop being to use the local household waste sites to dispose of their broken blasters and other electrical equipment.

Duncan Simpson , Director of sales and Marketing for Valpak commented that “Valpak is very happy to support the campaign to recycle more electrical and electronic equipment. Ensuring the message is heard throughout Kent, engaging all householders to get behind the force for good in recycling and making sure more materials end up being recycled rather than lost to the waste stream. We wish everyone the best for Recycle Week and encourage as many householders in Kent and further afield to think about dropping off all their old waste electrical and electronic gadgets and gizmos to the nearest recycling centre…..even their old light sabres.”

© 2015

13 March 2015

SWEEEP Kuuskakoski are proud to sponsor UH Racing, one of the most successful UK Formula Student team of all time, currently ranked 29th in the world out of over 500 teams!

UH Racing was founded in 1997 by University of Hertfordshire students competing in the IMechE Formula Student - Europe's most established educational motorsport competition.

Formula Student challenges universities from across the globe to design and build single-seat racing cars in order to compete in static and dynamic events. This year UH Racing hope to win both Formula Student UK at Silverstone and Formula Student Germany at Hockenheim, adding to the teams 18 year history of countless awards, using their cutting edge petrol, electric and hydrogen powered cars.

Supporting the UH Racing teams heritage of success has enabled Sweeep Managing Director and former British Touring Car Champion Patrick Watts to bring together his passion for both motorsport and engineering. Funding has helped develop the differential internals of the new car, which have been designed and assembled by the students, and provided tyres to allow valuable testing time before this years championship.

Patrick says ‘There is a very close parallel to the challenges of motorsport and the challenges of separating waste electronics. Both require innovative thought and the careful logging of differences that small mechanical changes can make to the performance development of the machinery whether it be a racing car or a screen separator. I would like students of Hertfordshire University to see that the talents they are showing with their racing project can be used in other industries with the same thrill of winning, maybe not at Monaco but at Sittingbourne, not getting a silver trophy but saving the Planet as a reward!’

https://www.facebook.com/pages/Sweeep-Kuusakoski/473220882747404?fref=nf

© 2015

20 February 2014

The repair parties for broken appliances

Are you a person who throws away their broken phone, laptop or camera rather than get it fixed?

The Restart Project aims to encourage people in the capital to use their electronics for longer by learning repair and maintenance skills.

BBC London's Charlotte Franks visited one of the projects repair events and spoke to Friederike Hanisch, from the Restart Project, and Justin Greenaway, from recycling specialist SWEEEP Kuusakosi Ltd

BBC News clip here: http://www.bbc.co.uk/news/uk-england-london-26248893

© 2014

25 March 2013

Zero Waste is no longer a utopian dream. The reality, which policymakers and waste producers increasingly recognise, is that waste must end if our world is to become sustainable.

Resource depletion, climate change and rising consumer awareness and power are shaping the challenges that businesses, public authorities and our society must face. More and more organisations, large and small, want to be part of the sustainability solution. The Zero Waste Awards will recognise and reward them.

Caroline Spelman, Secretary of State, Defra "We are committed to working towards a zero waste economy as part of the transition to a green economy and our commitment to be the greenest government ever. Communities and businesses can help us become a first-class zero-waste economy and unlock the real value in the goods that people no longer want."

SWEEEP Kuusakoski is proud to be a Silver Award Winner at the Lets Recycle 2013 National Zero Waste Awards. This award is recognition of our year on year recycling quality improvements which has only been made possible by continued investment and innovation. No greater example of this is our world first Cathode Ray Tube lead removal furnace.

© 2013

01 December 2012

SWEEEP Kuusakoski is tackling a global challenge thanks to a commercial world first.

The company has invested £2m in developing the world’s first commercial scale glass furnace making it possible to recover lead and pure glass from the leaded cathode ray tube (CRT) glass in old televisions and computer screens.

The new facility recovers one kilogramme of lead from each of the 4,000 CRTs it can process a day by heating the granulated leaded glass to 1,000 degrees centigrade.

As a result of the investment, SWEEEP Kuusakoski is able to reprocess approximately 10 tonnes of CRT glass a day, from 60 tonnes of CRTs.

The new furnace was officially opened on Friday 30 November, by the Rt Hon Michael Fallon, MP and Minister of State for Business & Enterprise. He was joined by His Excellency Mr Pekka Huhtaniemi, the Finnish Ambassador to Great Britain; and Mr Gordon Henderson, MP for Sittingbourne & Sheppey. The 150 guests also included representatives from the recycling industry and local authorities, as well as the company’s senior management.

Speaking at the opening, Rt Hon Michael Fallon, said: “SWEEEP Kuusakoski’s new furnace will help tackle the growing global recycling problem of how to recycle old televisions and computer screens.

“Their continued success, employing more than 150 people, is great news for Kent. The green economy is at the heart of our economic recovery and the UK recycling industry has a very important role to play.”

Justin Greenaway, contracts manager, SWEEEP Kuusakoski “Innovation in industry is part of the UK’s heritage and this is still very much the case with the opening of the SWEEEP Kuusakoski waste TV glass recycling furnace.

“Waste TV glass is a global issue and the UK recycling industry is at the forefront of providing the solution. The drive for greater resource security is an opportunity for sustainable economic growth and it is pleasing to be part of this.

“Through the work with our technical partner Nulife Glass, we have successfully commercialised a UK developed technology and can now recover large quantities of lead that would otherwise have harmed the environment.”

The company has gained end of waste status from the Environment Agency on the cleaned x-ray sorted panel glass. It has successfully established sustainable markets for the recovered lead, the front of screen glass, and the former leaded glass from the rear of the screens, generated from the recycling process.

The new furnace is the result of a high level development collaboration between SWEEEP Kuusakoski and inventor Simon Greer, and is powered totally by green energy. To ensure the company minimises it own impact on the environment it has recently installed a photo-voltaic system which generates approximately 50KWp, enough to power 12 households for a year and saves approximately 28 tonnes of CO2 emissions per year.

© 2012

10 July 2012

Schools recycling race is down to the wire

More than 12,000 young people joined the challenge to see which school could collect the largest amount of waste electrical and electronic equipment (WEEE) during the school year.

Linked to the national curriculum, the “WEEE Free” Week project was offered to every school in Medway last autumn, including pre-schools and infants schools, in a bid to raise awareness of how to correctly dispose of waste electrical and electronic equipment.

The competition was run in partnership between Medway Council, SWEEEP Kuusakoski, and Veolia Environmental Services. Each school was provided with a bright pink skip for one week, which became the collecting point for everything from old computers and mobile phones to kettles and battery powered toys. A total of 33 schools have now managed to collect more than 24 tonnes of electric and electronic waste between them.

The competition has resulted in a tie between two schools, as each has recycled exactly the same amount per head. These were Featherby Infant and Nursery School and Silverbank Park who managed to collect 9.88kg of electrical waste per student.

Both schools will receive £500 from Veolia and a tour of the SWEEEP (Specialist Waste Electrical and Electronic Equipment Processor) factory, where all collected materials are recycled.

Sherwin Knight Infant School have won the £300 second prize for recycling 6.57kg per head, with the £200 third prize going to St James’ CE Voluntary Aided Primary School for collecting 6.29kg per head.

Medway Council’s Portfolio Holder for Community Services Cllr Phil Filmer said: “I’d like to congratulate the winning schools for their excellent efforts. This project is the first of its kind in the south east and I hope it will help us to continue to raise awareness among all ages about the importance of disposing of electronic waste responsibly.”

Contracts Manager SWEEEP Kuusakoski Justin Greenaway added: “Every school involved with this needs a pat on the back as their enthusiasm has been terrific. The raw materials from waste electronics are a valued commodity containing numerous rare earth metals. Diverting 24 tonnes of waste that could otherwise have gone to landfill is to be commended”.

Clement Gaubert, Veolia Environmental Services’ WEEE Scheme Manager, “We have worked with SWEEEP Kuusakoski and Medway Council on WEEE recycling for a number of years and were delighted to sponsor the WEEE Free Week competition, which has been a fantastic success. We would like to congratulate the winning schools and thank all those who took part and also encourage Medway residents to recycle old electrical appliances at their local Household Waste and Recycling Centres or small WEEE bring banks.”

© 2012

23 March 2012

SWEEEP Kuusakoski helping to prevent climate change.

In keeping with our commitment to protecting our environment and helping to prevent climate change, we have invested in photovoltaic technology on our site.

Carbon dioxide (CO2) is one of the main greenhouse gases that contributes to climate change. Just under half of the UK’s man-made CO2 emissions come from energy we use every day, at work, at home, and traveling.

Our PV system generates approximately 50KWp which is enough to power 12 households for a year. It is good for the environment as it produces no greenhouse gases, no noise and no waste and in doing so saves approximately 28 tonnes of CO2 emissions per year.

© 2012

13 February 2012

SWEEEP Kuusakoski was awarded the first ever Recycling Business of the Year Award for its on-going investment and developments in the waste electrical and electronic equipment recycling sector.